As advances in technology enhances both the efficiency and competition between businesses and enterprises in nearly every industry on the planet, advanced new technologies are being developed to assist in the race to stay competitive. A good example of this would be the packaging and distribution industry, where technological advances are improving workplace operations within a constantly shifting landscape.

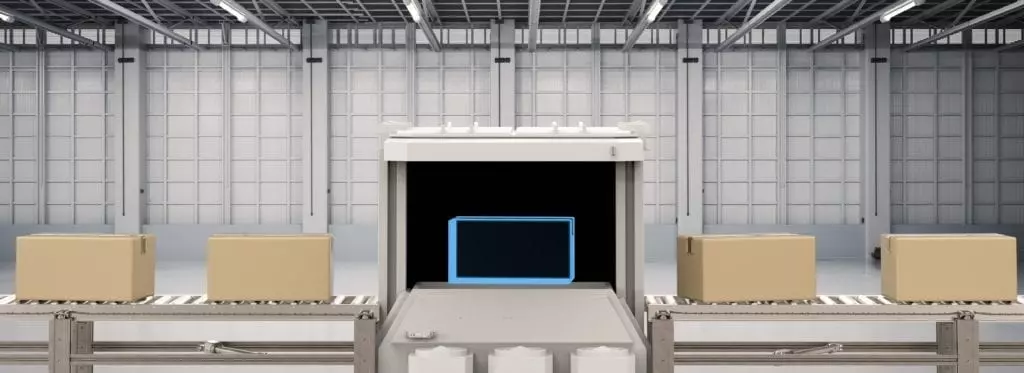

Artificial intelligence and machine vision are two such technologies currently transforming how businesses and enterprises operate and, with AI-powered machine vision systems, packaging and distribution enterprises are able to keep up with the competition in ever more advanced ways.

In this article, we’ll briefly take a look at what AI-powered machine vision is and how it works before taking a look at a few examples of how it could help packaging and distribution enterprises improve their services in an ever-competitive landscape.

So, let’s jump straight in!

![]()

What Is AI-Powered Machine Vision?

As the name would suggest, artificial intelligence-powered machine vision is a combination of both machine vision computing technologies and self-learning AI software with the aims of not only improving existing machine vision systems, but also improve upon the existing rule-based approaches utilised in existing solutions.

Through the AI subfields of machine learning and deep learning, machine vision systems are becoming capable of acting without being specifically programmed to and learning for themselves through experience.

According to Wallace Latimer, Sales Director at FISBA LLC in an interview with AIA, “AI is the next step where we take things that are not easily characterized or non-linear and give them to the machines to create that next level of repeatability,” It is hoped that AI systems can improve upon the degree of variation within the parts they inspect. Latimer went on to state, “Whereas linear algorithms create a very narrow bucket, AI/deep learning creates bigger buckets that can accept more variation.”

While there is currently much excitement centred around anything artificial intelligence touches, experts are currently predicting that the full benefit of AI-powered machine vision systems won’t be see for another 3-5 years as computational capabilities improve over time to accommodate more advanced functions and applications.

Why Is It Needed?

With increasing consumer demands and the advent of innovative and cutting-edge technologies such as those included in this article, industries across the globe are racing to see how they themselves could apply and benefit from new and powerful technologies.

However, as more and more businesses and enterprises have begun to implement and adopt technologies such as machine vision systems, the race to stay ahead of the competition in industries such as packaging and distribution has become tight. In order to both stay competitive and utilise advances in other technological areas, the need for enhanced systems has arisen.

In order to meet such demand, new systems have been developed that encompass various aspects of newer technologies such as artificial intelligence and machine vision in order to further enhance and improve them. For those working within packaging and distribution, AI-powered machine vision is a powerful new tool at their disposal to assist and improve operational efficiency and decision making.

It’s Benefits

AI-powered machine vision systems would bring with them various improvements and enhanced features; however, three particular benefits stand as being very much applicable to the packaging and distribution industry, and it is these three benefits that we’ll turn our attention to now.

Quality Control

Quality control is an essential element of both packaging and distribution and machine vision systems are currently capable of a vast variety of detection and notification functions. They do have their pitfalls though, as most will need to be recalibrated or reconfigured to suit the different varieties of items going through the quality control process.

However, with artificial intelligence and deep learning, machine vision systems would be capable of adjusting to a variety of different parameters and configurations so as to provide optimum detection capabilities to a variety of different products or parts.

Classification

As with quality control, machine vision is becoming an integral part of the classification process. By recognising the outlines of products and parts, machine vision can then follow their rule-based approach to go on to classify the object.

However, with AI-powered machine vision systems, the variety of images and the parameters used to calculate what they are can be expanded upon to greatly improve the accuracy and applicability of machine vision systems for classification of packaging and goods for distribution.

Real Time Tracking

Tracking products and parts throughout their time within packaging facilities and distribution centres is a great way to keep track assets and inventory and also streamline operational process to be more efficient. In current systems, this tracking is not always as efficient as it needs to be.

With artificial intelligence assisting machine vision systems, tracking of objects can be done in real-time along alongside tracing and data management functionalities to further improve the tracking capabilities of existing machine vision solutions.