AI algorithms, especially within the field of Machine Learning (ML), need lots of data. The more quantity and relevant data, the faster and more precise these algorithms will be. But processing lots of data is no easy task. The computing power required to process massive volumes of data and build an efficient AI system is outside the scope of traditional consumer-grade computers.

In fact, the brain of consumer-grade AI devices such as Amazon Alexa and Google Home does not exist on the device itself, but rather on the cloud. Without the intelligence coming from entire cloud data centers, namely AWS and GCP, Alexa and Google Home wouldn’t be a reality.

But today, this intelligence can be decentralized and be brought closer to where the data is— at the edge. An Industrial GPU computer running on the edge can run simple AI algorithms, and get insights without relying entirely on central cloud platforms.

Decentralizing AI and Running it On the Edge

Today, most AI algorithms are usually executed in some off-shore cloud data center, just like Alexa and Google Home AI-enabled devices. Although having access to powerful AI brains on the cloud is fantastic, it also introduces new challenges, especially for the industry:

- How to ensure reliable and low-latency communication to these off-shore AI servers?

- How to handle massive volumes of data in real-time?

- How to scale AI systems quickly?

- How to run AI in remote and harsh environments?

- How to ensure consumer data is protected?

Questions like the above drive the need to handle data differently— to cut its traveling distance, make it smaller, pre-process it on-site, etc. The answer lies in decentralizing and distributing the data processing power.

An intelligent edge uses edge computing to help devices (IoT and IIoT) send and get their data processed by different edge AI models. With Edge AI, the AI algorithms are processed on-premises (on local hardware) without requiring an Internet connection to an off-shore AI cloud server. All data generated on-site is processed in real-time, which helps reduce the latency of industrial applications exponentially.

Of course, cloud computing is still an essential component of AI, but it is not a unique solution. AI algorithms running at the edge might not be as powerful and experienced, as those running on the cloud. Still, edge AI can generate some insights, or even assist in pre-processing all data before sending it off-shore for further analysis.

Running AI Algorithms On-site: The Industrial GPU Computer

Running Artificial Intelligence on edge can be highly beneficial for demanding industrial-grade applications. Edge AI means more precise automation, quality control, faster decision-making, more safety, and lower costs.

The LEC-2290 is a high-performance industrial GPU computer capable of running AI and ML algorithms at the edge. This industrial computer with high-performance GPU capabilities can perform faster image processing, offload tasks from the CPU, perform more rapid calculations, etc.— An excellent option for powering the edge AI.

LEC-2290 Highlights

A crucial distinction is that this appliance’s computing capacity can be expanded with GPUs for video processing and CPUs for AI algorithms.

LEC-2290 Specifications

- CPU: The Intel® Core™ i7-8700T processor provides 12MB Cache and up to 4.00 GHz.

- RAM: 2x DDR4 2133/2400 SO-DIMM. The memory allows a maximum capacity of 32GB.

- Graphics Oriented. The integrated graphics card, Intel® UHD Graphics 630, helps with applications that require hardware-acceleration, such as H.265/HEVC 10-bit encoding or transcoding. LEC-2290 also supports GPU expansion and comes with HDMI outputs.

- Rich I/O: The appliance comes with a broad input and output options. Four USB3.0, six D-Sub RS232/422/485 Serial ports, and 8 DI and DO ports (Digital input/output for distributed control systems).

- Audio input and output: LEC-2290 comes with one mic-in and one line-out for audio applications. Additionally, it supports codec TSI 92HD73C.

- Ethernet capabilities: Two GbE RJ45 and four PoE (Power over Ethernet) RJ45 @IEEE 802.3. The total PoE budget of the four PoE interfaces is 60W (enough to power a couple of video cameras for surveillance)

- Storage: LEC-2290 comes with two removable HDD/SSD external slots w/ RAID and one mSATA.

- Powerful wireless expandability. LEC-2290 comes with a PCIe slot that allows LTE modules such as PGN-300 and PGN-600. These two modules are certified to be PTCRB and AT&T-ready and compliant with CBRS (Band 48) and FirstNet.

- Operates in harsh environments: Its fanless design is capable of tolerating temperature from -20°C to 55°C. The device is also capable of working under harsh and constant vibration scenarios.

Lanner’s Industrial GPU computer, LEC-2290 supports various drivers, Windows 10 IoT 64bits series, Ubuntu 16 and above, Fedora 25 and above, CentOS 7 and above, and Linux (Kernel 3.12).

LEC-2290 in Action

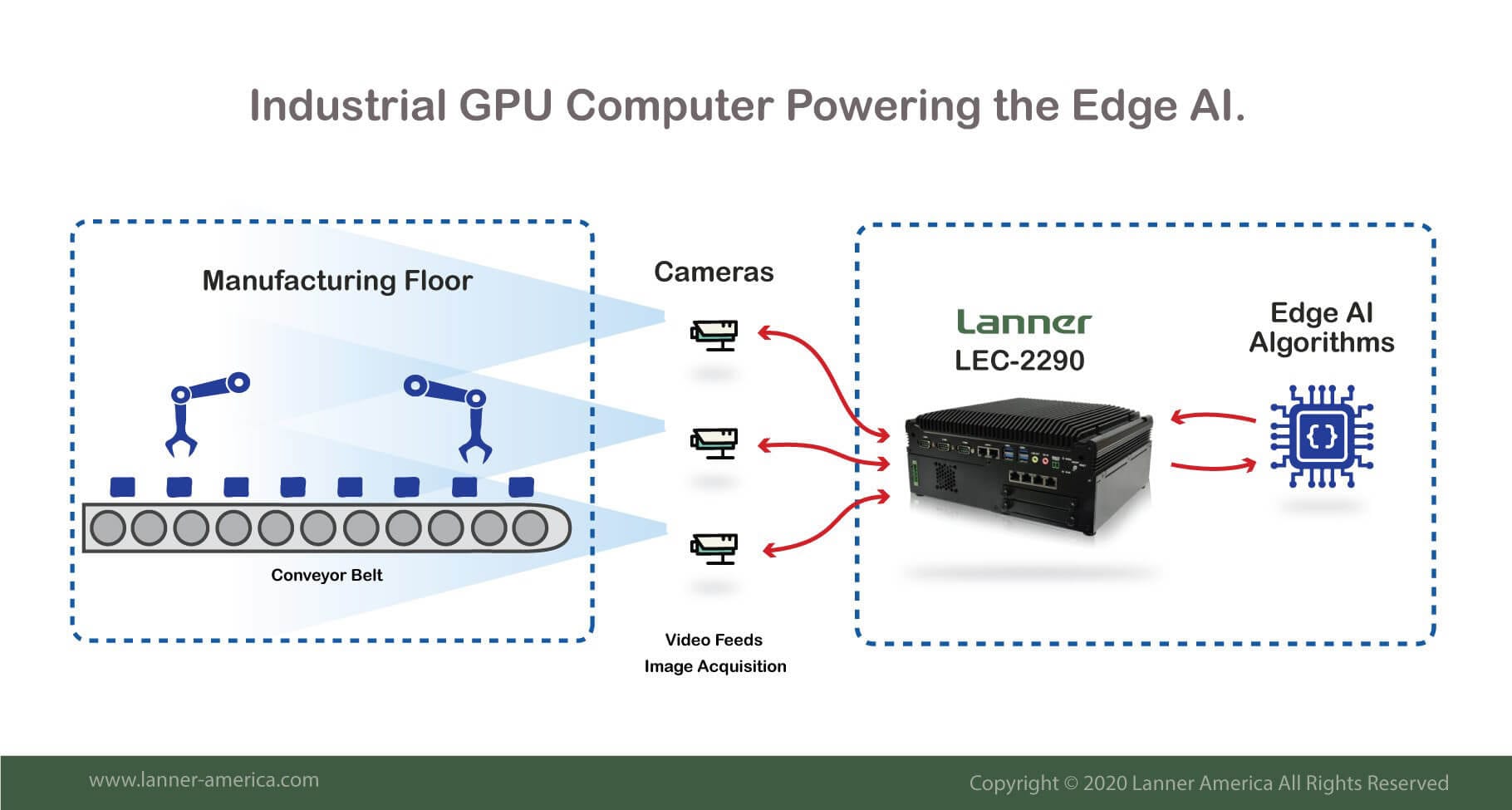

The diagram below shows the industrial GPU computer in action. Data is collected from cameras or sensors, fed into the industrial GPU computer deployed on the edge via a mini data center or distributed edge infrastructure. The LEC-2290 runs the AI algorithms, usually third-party sources, and processes all data on-site.

The following are examples of common use cases of the industrial GPU computer LEC-2290 for Edge AI.

Manufacturing precision and quality

Running AI-algorithms from Machine Vision to Machine Learning can guarantee more precision and quality control down the manufacturing floor. The cameras and sensors deployed across the manufacturing plant collect and feed data into the industrial-grade GPU computer, which processes it and creates AI systems. The LEC-2290 is an excellent industrial AI edge gateway for manufacturing precision and quality.

Physical security and video surveillance

The LEC-2290 is an industrial PC with GPU processing capability. It can run AI-based vision analytics more efficiently than any traditional industrial CPU. The appliance collects image data from cameras and, in real-time, performs AI-video analytics, to identify suspicious objects, unidentified faces, crowds, vehicles on restricted virtual geofences, etc.

Thermal imaging analytics computer

Thermal imaging technology became especially useful amidst the COVID-19 when airports and other entry points were trying to screen for fevers. Instead of having a security agent using a handheld thermometer to scan each passenger, an industrial thermal imaging analytics computer can process data quickly and precisely, without requiring physical contact and delaying passengers through long lines.

Lanner’s industrial PC with GPU, LEC-2290, performs these process-intensive video analytics algorithms. It takes massive volumes of thermography data from thermal cameras and processes video analytics in real-time.

Next Steps (Final Words)

Industrial-grade applications, such as the ones mentioned above, can be demanding. They might produce large volumes of data; they need to be ready to scale up and down quickly, not rely 100% on third-parties such as ISPs or cloud providers, or even leave all raw data within border network perimeters for added security.

The traditional AI-centric cloud data center is not optimal for such industrial applications. Slight network degradation or latency in such applications can be a deal-breaker. So, the processing power needs to be drawn closer to where the data is being generated— at the edge.

The LEC-2290 is an amazing industrial GPU computer with intelligent edge capabilities. Its ability to expand GPU can make it a better unit for processing resource-intensive computer vision algorithms.

For more information on LEC-2290 or other intelligent edge appliances, contact a Lanner’s sales representative.