Modern SCADA systems are currently being transformed by the advent of Internet of Things (IoT) and cloud computing technologies that can provide scalability, enhanced interoperability, and better security across a wider range of technologies than ever before. This transformation is building what’s been dubbed the fourth generation of SCADA systems and is also a part of a much wider technological push known as the Fourth Industrial Revolution.

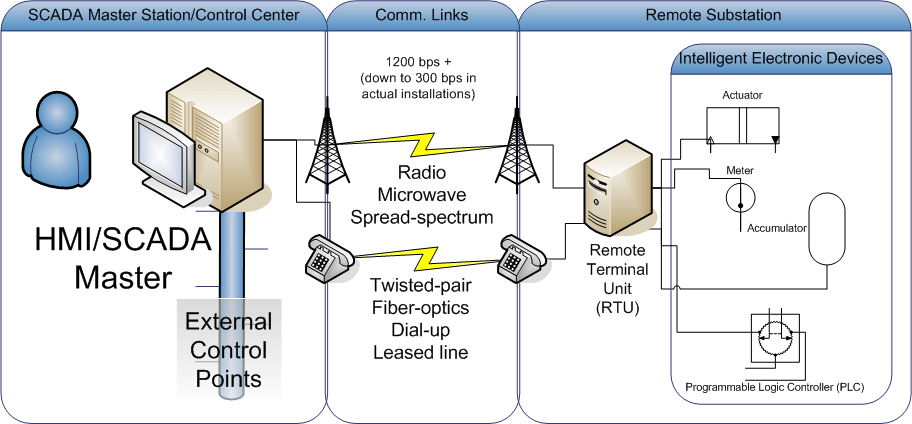

SCADA systems are usually implemented in order to manage and monitor physical processes via the use of sensors, programmable logic controllers, industrial computers, networked data communications, and graphical user interfaces. Their widespread adoption has seen them become integrated with a huge number of everyday processes, from managing the transmission and transportation of both gas and electricity, to the running of traffic management systems and other intelligent transportation networks and features.

With IoT and cloud computing technologies, however, many new applications and upgrades for these systems have been designed and developed to further integrate SCADA systems into the future.

4 Generations of SCADA Systems

Now, with all this talk of fourth generation SCADA systems, you may be thinking “Hold on, what were the first three?” So, let’s briefly go over the differences and abilities of the four generations of supervisory control and data acquisition systems.

First Generation SCADA

The first SCADA systems that were used operated on larger minicomputers, computer systems that were much smaller than the mainframe and mi-sized computers also available at the time. These SCADA systems were not networked as network services did not yet exist and thus, early SCADA systems were completely independent with no further connectivity to other systems available, or even possible. First generation SCADA systems became redundant when back-up mainframe systems were connected to all the remote terminal unit sites and then used if there was ever a failure in the primary mainframe system.

Second Generation SCADA

Second Generation SCADA systems had information and command processing distributed across multiple stations that were then connected through a large-area network (LAN) using proprietary communications protocols. This meant that information could be shared in near real-time and that each of the connected stations was responsible for a specific task or operation. Security for SCADA systems was usually overlooked at this time as few people besides the developers knew enough about these systems to analyse them and evaluate how safe they were from exploitation. Second Generation SCADA systems also provided some cost savings compared to their First generation parent models.

Third Generation SCADA

As is quite normal with any functional technology or applications, cost savings continued to be a driving force behind the development of third generation SCADA systems as an increased focus on network design meant that SCADA systems could be spread much further across multiple LAN networks, an architecture known as a process control network (PCN). Using networked architecture, complex SCADA systems were able to be reduced down to their simplest components and connected through standardised communications protocols. This in turn allowed further cost savings to be made by businesses and organisations that implemented more complex SCADA systems across much larger geographical distances.

Fourth Generation SCADA

Returning back to much more recent times, the fourth generation of supervisory control and data acquisition systems has mainly be driven by advances in cloud computing and the continuous growth of the Internet of Things. Using IoT and cloud computing technologies such as WebHMI and HTML5, Fourth Generation SCADA systems are able to report status in real-time from remote sites spread in far distances as well as take advantage of cloud computing environments to implement much more advanced control algorithms. Security for SCADA systems has also received a huge increase in focus thanks in part to security concerns about the Internet of Things and cloud computing. This in turn has seen many developers and manufacturers take up a “security-by-design” approach to SCADA, cloud, and IoT systems.

Drivers of Fourth Generation SCADA

The advent of the Internet of Things and cloud computing has fundamentally changed how, not only SCADA systems themselves, but various other monitoring, supervisory control, surveillance, security, and management processes are dealt with across many different industrial and commercial sectors. One of the main issues with the growing implementation of IoT and cloud-based technologies in SCADA systems is the way in which decentralizd data is managed by SCADA systems. In typical non-IoT SCADA systems, data is stored in specific programmable logic controller memory addresses. However, when using SCADA systems with integrated IoT technologies, data may come from a whole host of different sensors, databases, and controllers.

One of the solutions proposed to tackle this issue is data modelling. Using this method, a virtual representation of all the different devices and units connected to a system is built inside the SCADA system. These representations include address mapping data as well as other useful information that could be required by other parts of the system. SCADA is also a vital system in the ongoing automation revolution, alongside other technologies such as artificial intelligence (AI) and wireless communications technologies. With the continued implementation and development of technologies such as 5G wireless communications networks and advanced AI analytics in cyber security, fourth generation SCADA systems and the ones to come in future could look very different from their first-generation ancestors.