The massive amount of data generated by Industrial IoT devices, from cameras to sensors, must be processed in real-time. Although stored data is useful for insights and predictions, when it comes to mission-critical Industrial production and monitoring, data must be processed and analyzed right there.

However, it is very challenging to analyze critical data on-premises or even send it to a cloud service, when local processing resources are limited.

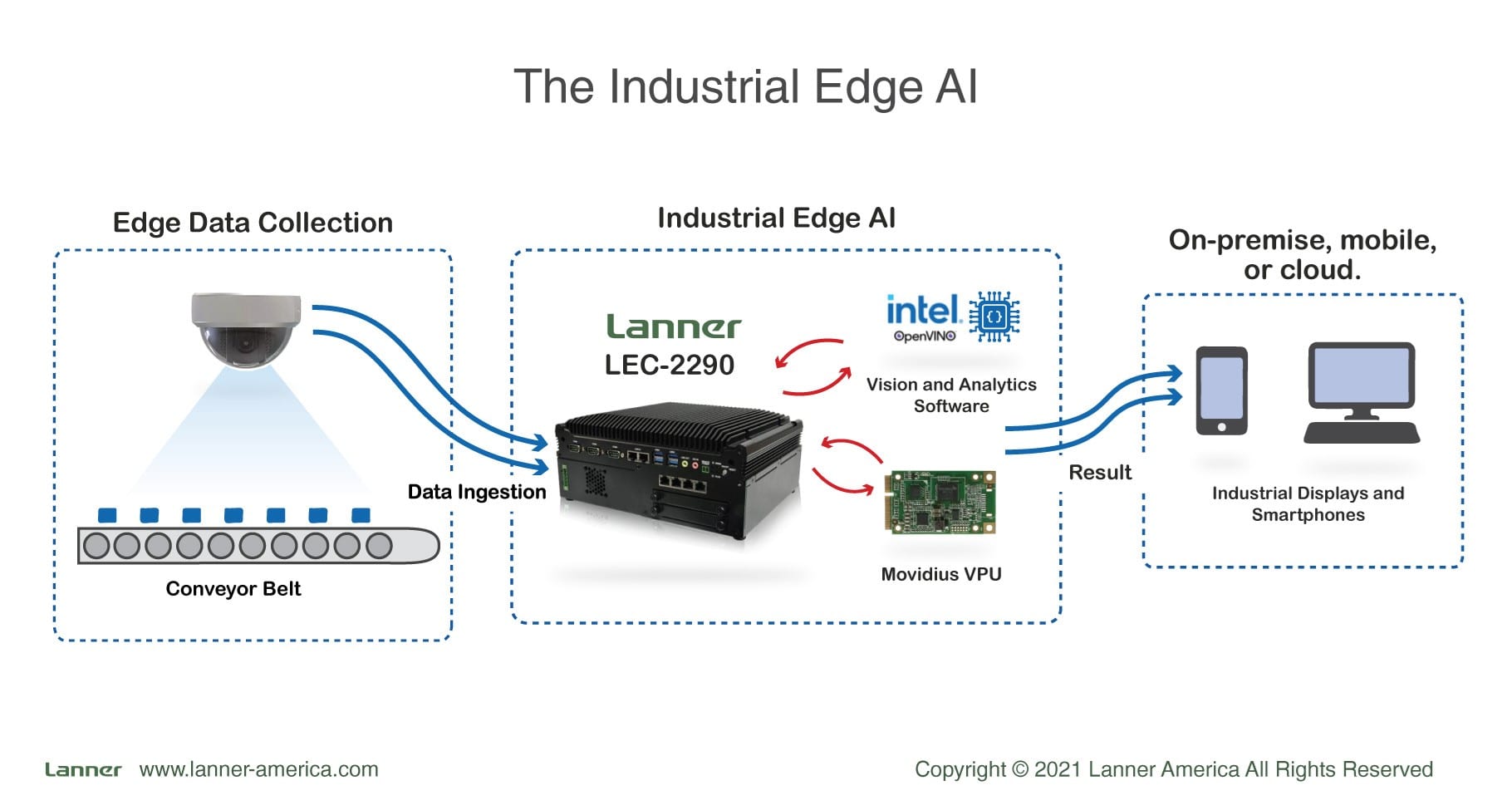

We will be reviewing Lanner’s A.I. Edge Computing Start Kit for edge analytics that helps resolve these challenges. The kit combines Lanner’s LEC-2290 + Intel® Movidius™ VPU and Intel® Vision and Analytics. This bundle solution helps accelerate and simplify AI deployments at the industrial edge.

Challenges

Industrial or manufacturing tasks such as inspection or sorting can benefit from AI-based automation. An AI system can make intelligent decisions, inspect, and quickly sort out defective products. Better yet, it can provide insights on how to improve production line processes.

Although we might be able to generate valuable data at the industrial floor to make automation happen, our on-premise computers and IT equipment wouldn’t be able to process it.

Challenges for industrial AI and automation:

- Real-time data-intensive applications require massive processing power. Ordinary servers deployed at plant floors, do not have the adequate processing power to ingest big data and run AI inference algorithms.

- Cloud is not the right solution for deploying AI in mission-critical apps. Cloud might have the right servers to process big data, but the network infrastructure that leads us there is barely adequate. Network constraints lead to higher latency and more demand for bandwidth.

- Data privacy and security. Sending data for processing to an off-shore cloud server increases the attack surface.

Industrial AI Edge Analytics Starter Kit

Lanner provides the complete package, so you can bring AI to the industrial edge— manufacturing floors, plants, oil rigs, etc. This AI kit combines the hardware: Lanner’s LEC-2290 with Intel® Movidius™ VPU and the software: Intel® Vision and Analytics. The kit is designed to accelerate and simplify AI deployments at the industrial edge.

Lanner’s LEC-2290

LEC-2290 is an intelligent edge industrial computing PC with support for Intel® Core™ i7-8700T/i7-8700 and high-performance GPU capabilities. The computing capacity of this appliance is already expanded with Intel® Movidius™ VPU for powerful video processing and edge AI.

The LEC-2290 supports LTE and WiFi, but its wireless capabilities can be further expanded with LTE modules such as PGN-300 and PGN-600. These modules are certified for PTCRB and AT&T-ready and CBRS (Band 48) and FirstNet.

Intel® Edge Insights for Industrial

Intel® Edge Insights for Industrial is an open platform for machine vision and time-series data. The software can aggregate video/image series data and run AI analysis at the edge— without needing to send your sensitive data to an off-shore server for processing.

The Intel® Edge Insights is powered by the OpenVINO™ toolkit. The Open Visual Inference and Neural network Optimization toolkit (OpenVINO™) provides neural network performance to help developers create real-time computer vision applications.

Bundle Kits

Below are three bundle solutions offered by Lanner. At a basic level, they combine Lanner’s LEC-2290 edge appliance with Intel® Vision Analytics software. Intel® Vision and Analytics suite includes Intel® Edge Insight for Industrial AIoT reference application and the OpenVINO™ toolkit.

The Advanced AIEC Starter kits come with one network camera and the Intel® Movidius™ VPU. Intel® Movidius™ Vision Processing Unit (VPU) helps accelerate the system for resource-intense computer vision and edge AI algorithms.

Benefits

Instead of moving our data a long way to a cloud-based center for analysis and without relying on our network infrastructure to do this, edge AI takes a big shortcut. It brings the intelligence (AI and Machine Vision algorithms) and powerful processing, closer to where it is needed.

Since Edge AI decentralizes cloud-based AI and can process data in real-time, it can provide the following benefits.

- Predictive Maintenance. AI/ML and computer vision can help predict when certain industrial equipment could fail. Predictive Maintenance is helpful to prevent potential equipment downtime and avoid losing customers or revenue.

- Ensure productivity and quality. Automate manufacturing processes such as inspecting bottles, tires, welds, or textiles in a manufacturing production line. Additionally, edge AI and computer vision enable key technologies like Collaborative Robots (Cobots) and Mixed Reality.

- Remote video monitoring. Processing video at the edge can help with optimizing security surveillance or visual supervision. Applications like facial recognition or fever detection can help with building security. It allows AI-based authentication and factory-wide access to employees.

- Train new employees. Bringing intelligence to the edge also helps training new employees via Mixed Reality or collaborative robots. These technologies can help trainees interact with prototypes without risk.

Next Steps

For more information on the AI starter kit for edge analytics, please contact Lanner’s sales representative.

Photo by amin khorsand on Unsplash

Intel, the Intel logo, Movidius, OpenVINO, and the OpenVINO logo are trademarks of Intel Corporation or its subsidiaries.