While most have yet to grasp the concept of Industry 4.0, Lanner has long completed its Industry 4.0 product roadmap and is now introducing its intelligent manufacturing solutions for MES, machine automation and vision inspection, enabling early adoption and system testing for Lanner’s strategic partners in preparation for developing smart manufacturing controllers and for realizing the implementation of smart factories.

While most have yet to grasp the concept of Industry 4.0, Lanner has long completed its Industry 4.0 product roadmap and is now introducing its intelligent manufacturing solutions for MES, machine automation and vision inspection, enabling early adoption and system testing for Lanner’s strategic partners in preparation for developing smart manufacturing controllers and for realizing the implementation of smart factories.

Vision Inspection

Replacing human vision with machine vision for verification and testing tasks is a part of industrial automation, intended for achieving faster TTM and optimizing resources while at the same time lowering cost of ownership and improving risk management.

Successful implementation of machine vision for all production processes requires the upmost care in not only software algorithms compilation and system hardware selection, but also the software and hardware integration.

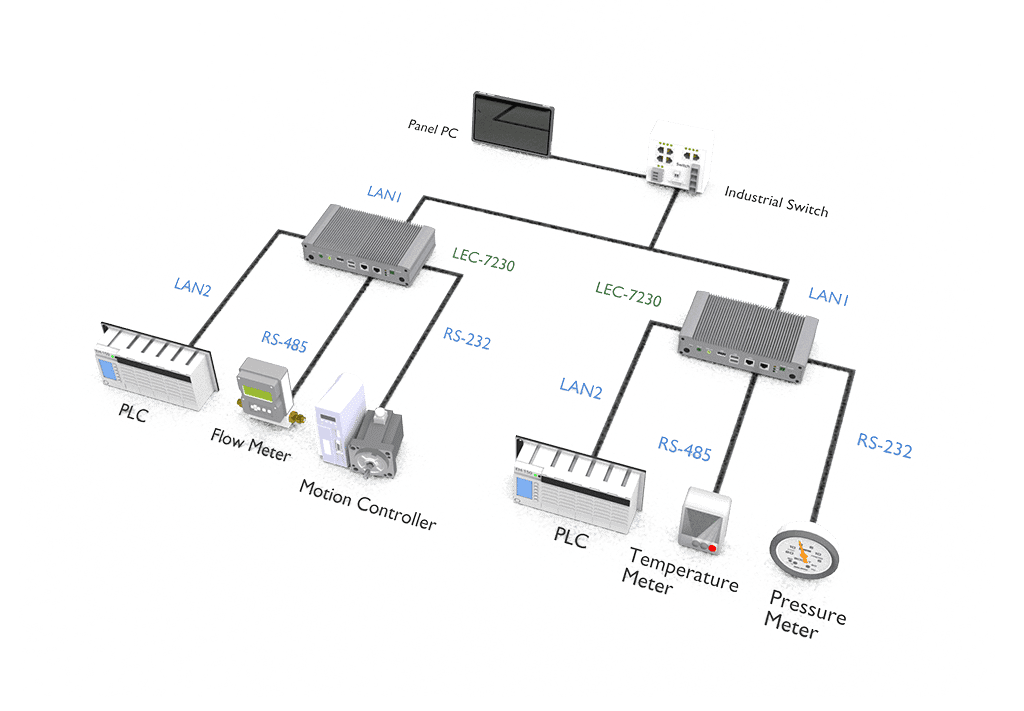

Machine Automation

Automation control solutions such as motion controllers are usually implemented for manufacturing SMT/PCB, semiconductor and LCDs and for operating machinery such as boilers and heat-treating ovens and switching on telephone networks. Hardware solutions for machine automation aim to facilitate minimal or reduced human intervention or even complete automation, not only streamlining the distribution of manpower and improving energy efficiency, but also ensuring production quality, accuracy and precision.

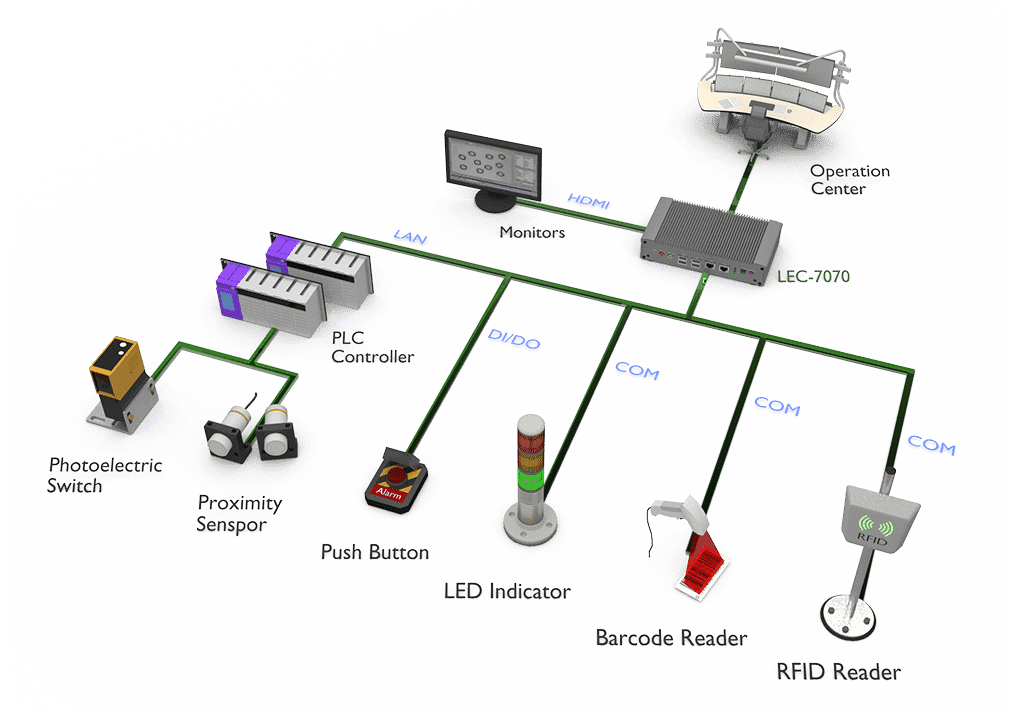

Manufacturing Execution System

As more and more automation takes place at factory floors, gone are the days when operators are expected to have all the information at their fingertips, rendering complex setup of displays and control panels obsolete.

Software-based thin client computing has now become ubiquitous in production automation, so too have the hardware appliances that can be customized and tailored for all industrial automation applications found at processing plants and manufacturing factories. Together with the availability of a variety of thin client management software, hardware appliances have evolved and changed in terms of their flexibility and capability, adding value to manufacturing execution systems (MES) by making administrating work stations in today’s factory environments significantly easier, safer and more reliable.