Asset Condition Monitoring

Predictive maintenance

Machine Learning

Overall Equipment Effectiveness

Leverage the Power of Real-Time Edge Data to Keep Assets Running as Planned

Customers want to adopt modern use cases to enable Industry 4.0 and Digital Transformation, but they lack the right technology to liberate the data locked in distributed assets. Challenges to implementing Industry 4.0 include complex data and systems, slow and expensive deployment, and a lack of clear ROI.

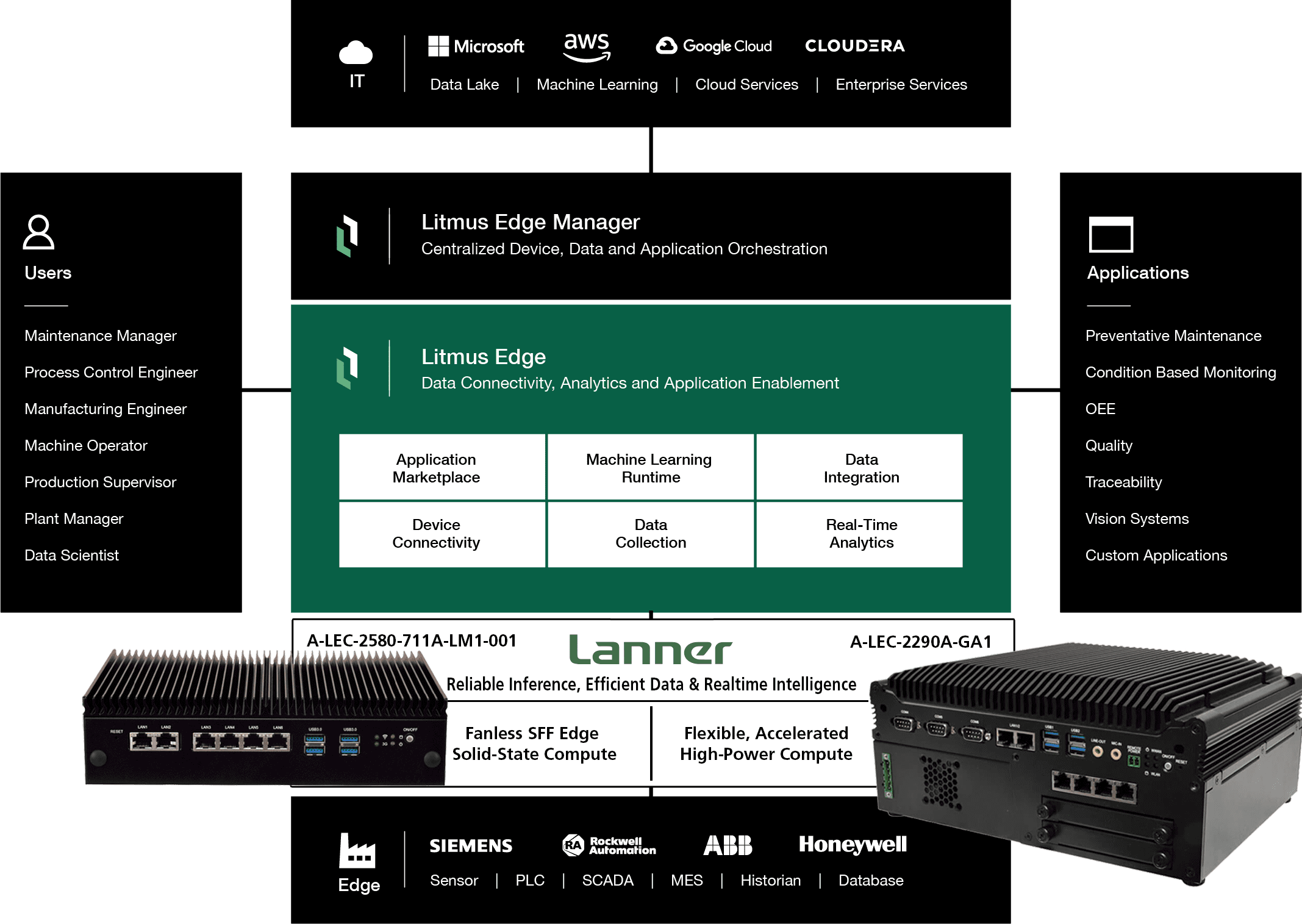

Litmus’ Edge platform brings a vetted and tested software platform with proven, extensive hardware compatibility that is able to quickly integrate with world-class physical manufacturing assets (PLC‘s, CNC’s, sensors, robotic systems, SCADA) and the myriad of software and data intelligence components that currently drive them.

This Industry-leading software platform fits perfectly together with Lanner’s open & versatile industrial hardware to provide the connectivity and edge computing power necessary. Deliver clear ROI’s and accelerate your digital transformation to gain predictive maintenance capabilities, OEE (Overall Equipment Efficiency) intelligence and other key insights to maintain the competitive edge in modern manufacturing.

One Platform to Collect and Manage Data from All Industrial Assets

Integrate Data into Big Data and Cloud Systems for Advanced Analytics and Machine Learning

The Edge Platform for Industry 4.0

Lanner Industrial Hardware + Litmus Edge

Extensive I/O for both Modern and Legacy System Integration

With 8x Digital I/O, multiple serial COM and USB ports along with modern network gigabit+ interfaces you can integrate with a wide range of systems

Optimized for Secure Edge Communications

Powerful Processors enable multiple high-security protocols and encryption algorithms in real-time communications

Built for 24/7 Operation in Harsh Industrial Environments

Lanner’s hardware platforms bring proven reliability, with a purpose-built design that can withstand the harsh challenges in the industrial edge