Today, one of the biggest challenges with a 4G network in high density areas is that it needs to support under 70,000 devices in a single square kilometer. 5G, the most recent cycle of cellular innovation, is designed to handle such a massive number of connected devices, and still expand their speed and responsiveness.

5G is no longer a buzzword but a reality at the doorsteps of enterprise and consumer growth. It brings a shift from centralized to decentralized industries.

In the early 2019, Chicago-based Rush University Medical Center decided to embark on a significant installation of 5G. According to a statement by Jeremy Marut, the hospital’s chief enterprise architect, the hospital is also kicking off the development of a massive 11-story outpatient building. “That building is going to be a building of the future or hospital of the future,” he said.

As per this project, the entire Rush Hospital will be digitized, and all their services will be sent to the cloud. To make this a reality the hospital is already making a lot of investments on edge computing and 5G.

Why is the Industry Getting Interested in Private 5G?

4G is going over the limit.

With over 75 Billion IoT devices and machines predicted by 2025, generating not terabytes but thousands of petabytes of data. 4G can no longer provide the capacity to capture, analyze, and transmit these massive streams of data, especially in large factories and cities.

The fifth generation of mobile broadband technology, 5G, is viewed as the key innovation to empower a full scope of use cases such as the Smart City, Smart Factory, IoT industry, and more. Other examples will be found in the Enterprise and SMBs. The businesses will be empowered through the vast benefits of 5G, such as faster speeds, wider coverage areas, and improved security, and more.

Of course, 5G’s ultra-low latency and security will allow seamless cloud-based services for the consumer-grade, but these same benefits will take the Industry to a whole new level.

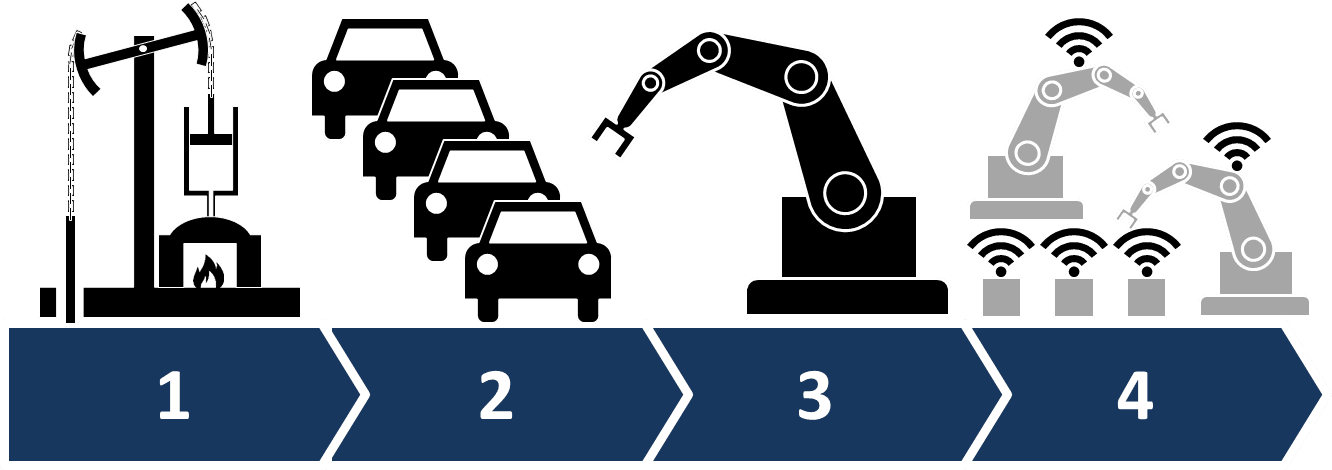

The Industry has been evolving over the years from mechanization, electrification, digitalization, and now wireless connectivity, which is referred to as the Industry 4.0. The later will give birth to smart factories filled with on-device processing and sensing, autonomous robots, edge computing services, and more.

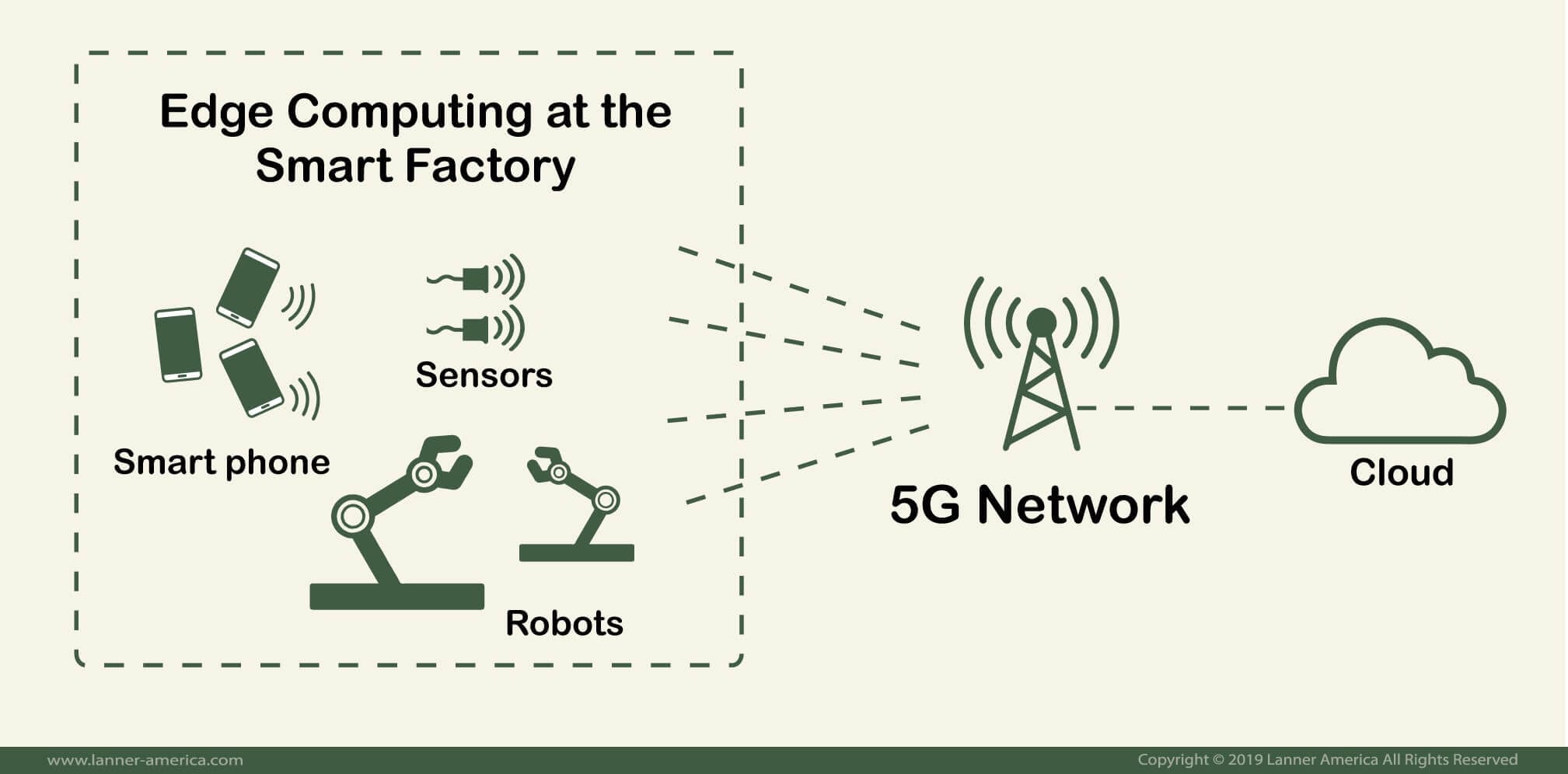

To be able to support this massive amount of generated intelligence data from smart factories, which will likely be sent to a cloud-native or containerized app, the Industry will need to rely on a private high-speed connection.

Private 5G is a new concept. It will be kind of the Wireless Local Area Network that we know today, but allowing thousands of devices at ultra-low latency speeds, moving at speed, and throughout broad areas. It will provide the kind of connection that new Industry 4.0 requires.

5G and Edge Computing, Pushing the Smart Factory

Samsung Electronics America (SEA) and Samsung Austin Semiconductor (SAS) are working with AT&T, to create America’s first manufacturing-focused 5G “Innovation Zone” in Austin, Texas. This first attempt to create a “Smart Factory” is designed with safety, security, and operational performance strictly for the manufacturing industry.

This new “Zone” will help give immediate insights into how intelligent assembling can get and also to improve the manufacturing business.

The capacity and throughput levels that manufacturing facilities such as the Samsung Austin Semiconductor require, could only ever be achieved with high capacity wiring.

But a factory needs some level of self-organization which is introduced thanks to interconnectivity and interoperability. All these functionalities are achieved through an encapsulation of technologies, namely AI, AR, cloud, automation, private 5G, and edge computing.

Bringing wireless broadband 5G into the equation and edge computing on-premises, the facility can eliminate wires, increase the capacity of collected data, and process data in near real-time.

To achieve the autonomous smart factory (Industry 4.0), full private 5G performance and the edge computing stack at the facilities will be required.

Private 5G Challenges for the Industry 4.0

In any technology, there is no one-size-fits-all.

There are 6 out of 10 manufacturers that admit that they have little progress towards achieving the Industry 4.0 initiatives. One of the main reasons is that there is a lack of knowledge of specific technologies that can boost this initiative.

One of the critical technologies that can open the door for the Industry 4.0 innovation and the smart factory is Private 5G.

It is evident that the primary goal of 5G is to overcome the current limitations of 4G. Although there is a lot of research and development in 5G, there are still a few key difficulties when it comes to Private 5G. The main challenges are:

- Spectrum allocation.

- Network design, build and deploy.

- Cost to build.

As opposed to the Private 4G/LTE (CBRS), which allocates a portion of the 3.5 GHz spectrum for the citizen’s use. One of the main challenges for Private 5G today is the availability of such licensed or unlicensed spectrum. Although there is a spectrum for 5G, it is at the hands of the governments and providers that need plenty, there is no CBRS just yet, as what happened with 4G.

But still, enterprises and Industry 4.0 leaders can benefit from licensed Private 5G, will likely get a portion of the spectrum from the providers, for a price.

Another challenge is that Private 5G will likely require high specialized skills to design, build, and deploy these networks. Engineering firms are expected to take on this challenge.

Deployment of 5G networks appears to be a challenge in some countries due to regulations which are still blocking 5G implementation. The technology also requires a new kind of infrastructure, which is not cheap. 5G needs a large number of small cells to address the scale of devices and speed, which in turn suggests substantial cost implications.

Starting with the Edge Computing and Private 5G?

Facilities such as manufacturing will likely be the first ones to adopt Private 5G. But these factories will need some sort of edge computing on-premises, whether a remote monitoring, data storage handling, or cobots (collaboration robots).

Remember that the main idea of edge computing is that it brings data processing closer to the edge of the network. It moves the intelligence to where it needs to be —closer to applications, devices, and clients.

Edge computing is recognized as one of the key technologies required to help with low latency. Edge devices require network availability, and especially with IoT devices, which are usually in close proximity. Additional high-performance computer hardware and radios that prioritize traffic are also vital to meet 5G latency goals.

Having this intelligence at the edge, supported by ultra-fast private 5G network connectivity to the cloud, will have unlimited benefits for these factories.

Which network appliances could make this happen?

Appliances that can make this happen need to support real-time analytics and mission-critical IoT automation.

An example of an Industrial IoT network appliance is the NCR-1510. This is a rugged device that can withstand the conditions of certain manufacturing environments. It is powered by Intel Atom 2~8 Cores. This network device has great performance for industrial-grade LAN functions. It can be used as an SD-WAN, or uCPE device.

The NCR-1510 is also compatible with Lanner’s Certified LTE modules PGN-300 and PGN-600. Both modules have acquired AT&T certifications while Verizon ODI certifications are in progress. PGN-600 is compliant with FirstNet and CBRS LTE network bands.

Final Words

5G technology is designed to manage a greater diversity of data services, rather than simple commuter-grade browsing/streaming or social networking. By itself, 5G will meet the high performance and broadband capacity that many enterprise and industry needs.

But for the Industry 4.0 and smart factories to work, they need more than connectivity. Their on-premises edge computing will “help” process data faster and lower latencies. It will move the application or content closer to the end-user, at the edge of the network.

The 5G + cloud computing approach will make latency to go rest in peace.