Manufacturers monitor CNC machines mainly to keep track of their efficient work time and count the units produced. Additional monitoring tasks may also include keeping an eye on the machine’s operational status and looking for deficient and worn out parts that could lead to significant overhauls.

A comprehensive CNC monitoring solution should leverage novel smart manufacturing technologies to improve these business processes and avoid significant maintenance expenses.

This smart manufacturing solution, including IIoT data collection and edge intelligence, will ultimately improve monitoring efficiency and even add intelligence into the process.

Summary

The IIoT sensors embedded on CNC machines at the shop floor can generate large amounts of rich data. But what’s this data for, if manufacturers don’t have the suitable industrial communications equipment to relay all of this data to an off-shore server on time?

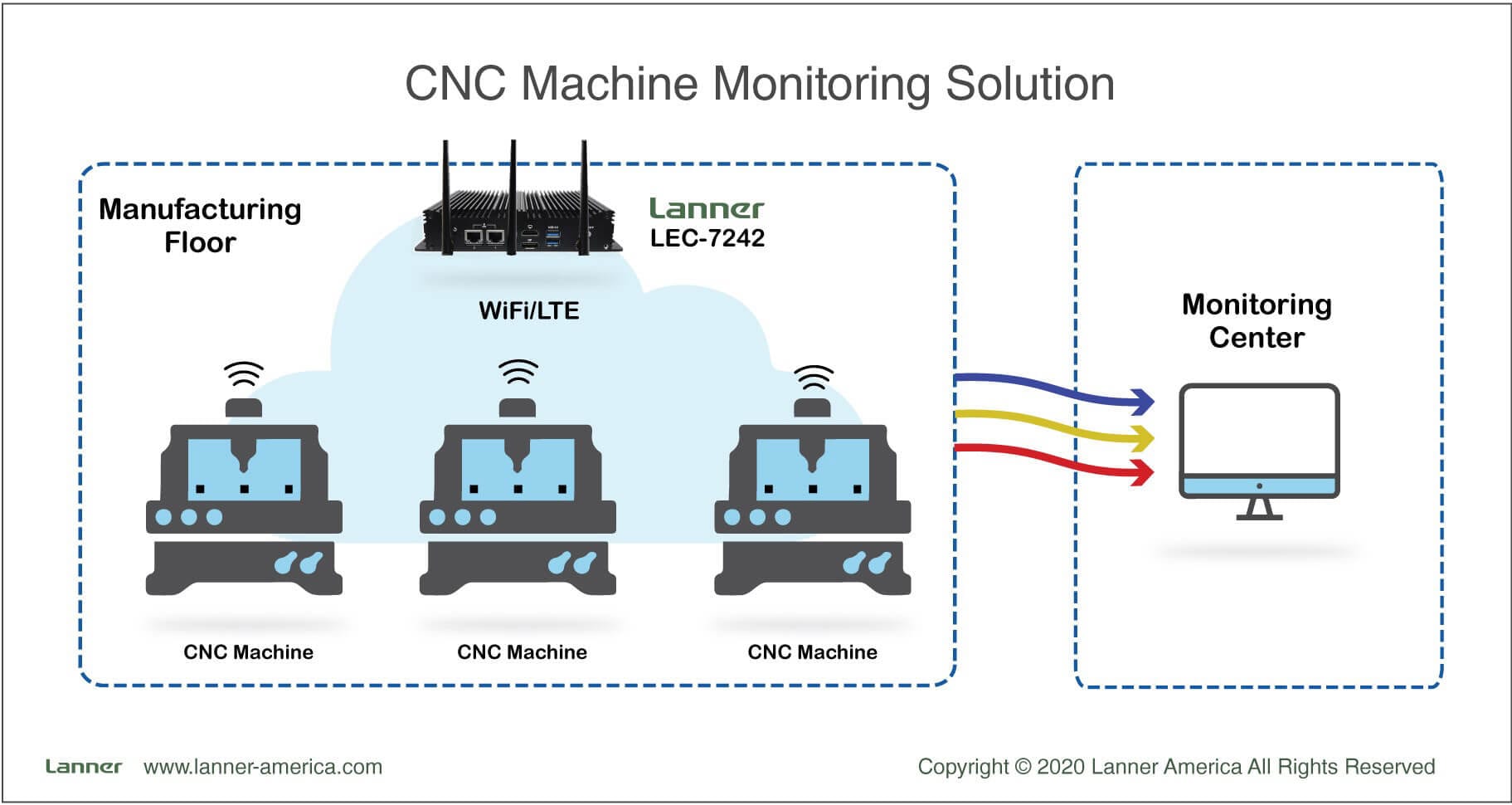

We will be reviewing a CNC machine monitoring solution that helps resolve manufacturers’ challenges. The data generated by CNC machines can be handled by Lanner’s LEC-7242 Industrial Wireless IIoT Gateway. This appliance pre-processes all data, integrates it, and forwards it to a monitoring server.

Lanner’s LEC-7242 comes with Intel® Apollo Lake CPU and is FCC/CE/PTCRB certified for LTE or WiFi. It also runs data analytics and machine learning specific for smart manufacturing.

Challenges

Manufacturers need to keep an eye 24×7 on the operational status and business processes of these CNC machines. They need to be on-site to avoid any loss or improve these industrial processes, directly monitoring the CNC machine.

- Manufacturers monitoring their CNC machine might face the following challenges: High demand for bandwidth and low latency. Operational CNC machines might produce large amounts of data. So, the communication between industrial sites and the monitoring center needs high bandwidth and low latency data communications. Forwarding large amounts of data continuously 24X7 from the shop floor by traditional networking devices can be challenging.

- Traditional IT devices can’t withstand industrial conditions. IT devices such as wireless gateways, servers, and computers deployed on the industrial floors are faced with harsh environmental conditions. These devices are not able to withstand these conditions and may fail quickly.

Solution

Manufacturers want to take full control in real-time, of their CNC machines. And not just by standing in front of them but monitoring them remotely from their back offices. From knowing a CNC’s overall equipment’s efficiency, its working time, and its pieces produced, to detecting early deficiencies in the machine’s process or the wear of any machine’s part.

A comprehensive CNC Machine Monitoring Solution encompasses all the stages of a Smart Manufacturing process: collecting, pre-processing, protecting, transfering, and monitoring of the data.

CNC Machine’s Sensors and Wireless Interface

A CNC machine uses its embedded sensors to collect data metrics, like cutting force, vibration, temperature, sound, current, etc. This data will provide the means to monitor processes and create additional useful intelligence, such as predictive maintenance.

CNC Machines’ board controllers and sensors may be connected via Serial, USB, Ethernet, or Wireless.

Industrial Wireless Edge Gateway

The Industrial Wireless Gateway provides security, data processing, and communication. It helps the CNC machine transfer data efficiently to a monitoring center, whether located on-premises or in the cloud. An advantage of an industrial wireless gateway is that it can integrate date from different IIoT devices through various peripherals and apply edge intelligence.

Lanner’s LEC-7242 is an industrial wireless gateway with Intel® Apollo Lake CPU and FCC/CE/PTCRB certification for LTE or WiFi. It connects to the CNC controllers via TCP/IP using WiFi or LTE. The LEC-7242 may also pre-process some data at the edge and forward it to the monitoring center.

LEC-7242 Key Features

- Processing: Intel Apollo Lake Celeron® N3350 / Atom® X5-E3940. Frequency from 2.4GHz / 1.8GHz (Core 2 / 4).

- Environment Tolerant: Fanless advanced passive cooling technology. LEC-7242 operates in a wide range of temperatures 0°C~50°C / -20°C~70°C.

- Wireless Expansion: 1x M.2 3042 B+M Key Socket w/ Dual SIM for LTE or WiFi. The appliance is FCC/CE/PTCRB certified for LTE or WiFi.

- Rich I/O: Serial Port (1x RS-232/422/485, DB9 Male), 2X USB3.0, and 2XRJ45 10/100/1000 Mbps ports.

Data Analytics and Machine Learning Software

LEC-7242 also runs intelligent IIoT edge computing software, specially built for smart manufacturing. This software provides real-time data collection, processing, analytics, AI/ML algorithms, and edge-enterprise data integration.

Monitoring Center

A monitoring station running the CNC’s control software is connected to the board controller or sensors on the CNC, through the Industrial Wireless Gateway. An advantage of using an IIoT wireless gateway such as the LEC-7242 is that the monitoring station can be located on-site or remotely.

The monitoring center may run additional analysis on the data (already pre-processed on edge) and create reports, alerts, and notifications. The agents on the monitoring center can then generate further data visualizations and statistics.

Benefits

The following are some of the benefits of using the CNC machine monitoring solution with LEC-7242:

Collect and analyze CNC data at the edge

IIoT edge computing appliances such as the LEC-7242 can run advanced analysis on the raw data collected on-site. Not having to transfer this data to an offshore server for analysis reduces the need for high bandwidth.

Remote monitoring and management

Manufacturers using an intelligent CNC machine monitoring solution can remotely keep track of business processes such as effective work time and the number of units produced. They can also monitor the real-time operational status of the machine or details of specific failing parts. Manufacturers may receive instant notifications and fault alarms.

Withstand harsh industrial conditions

The industry floor may be exposed to lots of variable harsh industrial conditions, from EM interference, vibration, humidity, wide temperature, etc. Traditional IT appliances are not built to withstand these conditions. LEC-7242 is a wide-temperature and humidity tolerant appliance designed for these conditions. It can be deployed in CNC machine shop floors.

Highly available communications

The industrial IIoT gateway is built for high availability— It comes with dual LTE and WiFi interface. Dual-SIMs allows link redundancy and uninterrupted communications. In case the WiFi connectivity within the floor shop fails, the LTE will take over.

Prevent major overhauls

The edge intelligence provided by Litmus Edge can introduce preventive monitoring. The data collected on-site goes through data-driven algorithms such as AI or ML, which can provide predictions on the status of certain vulnerable parts of a machine. Predictive monitoring helps prevent major machine overhauls and save a fair amount of expenses.

Next Steps

For more information on other Intelligent Edge Appliances or the CNC Machine Monitoring Solution with LEC-7242, please contact a Lanner’s sales representative.

Photo by Alexander Pütter on Unsplash