The reach of computers within companies has gone beyond office space and server rooms. With the advance of Industry 4.0, more and more computers are now on the production floor or in the field. This in order to monitor and control the production processes of the company. For some years, this has led to the design of new types of robust industrial computers, which are made for the most difficult conditions, even extreme while responding to the necessary computing requirements, being also used in specialized equipment.

One of the latest trends in such unfavorable conditions for devices is computers without fans. How do they work and what benefits do they have? What factors should we consider when choosing an industrial computer without a fan?

Fan of Fanless PC

The fans are used in the computers to eliminate the heat generated, and there is usually a fan with the power source, one that cools the CPU, and one or more fans in the computer case and there may be a fan on the graphics card. The use of alternative computer arquitecture (e.a. heat pipes) make possible to take away the heat from the processor and other parts that could generate high temperature.

Despite the popularity of the use of fans, there are some advantages of having a computer without any type of this device. Such as:

- No external waste. Some computer fans blow in and others blow out, depending on the location of the fan and the dynamics of air circulation in the box. When a computer fan blows inward, it carries not only fresh air, but also waste such as dust and dirt. These wastes can accumulate over time and interfere with the electronic components inside the computer, causing them to fail. By using a computer without a fan, the entry of dirt that can damage the computer is eliminated.

- No moving parts. The moving parts of a computer are susceptible to mechanical failures caused by debris, shock and vibration. Most, if not all, of the moving parts of a computer are fans. When a fan has a mechanical failure, it not only requires a replacement fan but also puts the stability and health of the computer in danger. As the temperature increases, the equipment may turn off unexpectedly. Some electronic components may overheat and be permanently damaged. With a fanless computer, the risk of mechanical failure of a fan and the resulting downtime and potential damage to electronic components is eliminated.

- Any Location. The computers without fan can be placed in places not suitable for equipment with fans. For example, there may be a need to locate a computer in an outdoor space exposed to rain or snow. While a computer with fans could not function if exposed to the elements, a computer without a fan could tolerate exposure.

- Silent operation. Almost all the noise that a computer makes comes from its fans. By eliminating the fans, the noise is eliminated. Creating a computer that works silently is an important consideration for some computers, such as meeting rooms or hospitals.

What factors should I consider when choosing a fanless PC?

We have stablished the huge plus it is for a computer to be fanless, especially for industry purposes. Nevertheless, that’s not the only, or even most important factor. We should also consider the following:

- Since the environment where the computer will be, depends on the application that will be given, this is a determining factor to choose our best option. For example, what type of operation will it be used for? Will it be the operating room of a hospital with a controlled and sterile climate? Or a production floor for electronic components? Think of an extreme case, a plant that cleans metal parts with pneumatic hand tools, generating a lot of metallic dust in the environment. Analyze this factor well to avoid spending on equipment that does not resist the conditions in which it will work. If the environment is extreme maybe you can even consider rugged device.

- As with any computer choice in general, we must evaluate the performance requirements of our computer. Will it be an operator station, process data from a PLC or even manipulate a robot? Nowadays there are many options of processors as powerful in the industrial pc world as in any other computer used in any other field. Read the technical specifications of the computers you are evaluating and even look for additional information specific of the capabilities of each one of the components (CPU, Graphics Card, etc.)

- This aspect is as critical as the performance since the whole point of having computers at the production floor is to be able to monitor all the information remotely, even from the cloud. So, we have to determine if, according to our business we only need Ethernet ports to communicate with the PC’s. Since one of the benefits of a fanless pc is that they can be installed in many more places, maybe you can even consider wireless connectivity, if it’s suitable for you system

- Since Industrial PC’s are not consumer electronics users oriented (due to being a more specific market with higher requirements on materials and specs) the price will be higher than regular pc’s. So you have to determine the cost/benefit rate. Do you really need a more expensive local PC with all its components or maybe just a terminal connected to a server through a remote session?

An excellent fanless PC example

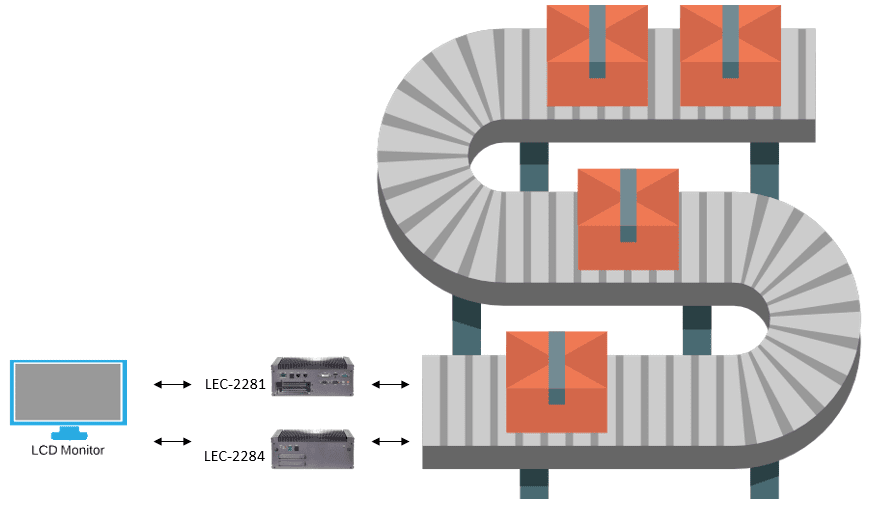

Lanner’s now introducing excellent Industrial fanless PC’s for machine automation and vision inspection, enabling early adoption and system testing for Lanner’s strategic partners in preparation for developing smart manufacturing controllers and for realizing the implementation of smart factories

Powered by Intel®’s 4th generation Core™ i7/i5/i3 CPUs with QM87 PCH, the LEC-2281 and the LEC-2284 offer either quad-core or dual-core processing power, demonstrating significant performance improvements over the 3rd generation Core™ processors.

The combination of high-performance CPUs, 16GB of DDR3L memory, a well-balanced number of COM/serial/USB ports, the onboard Intel® HD Graphics 4600 and the built-in HDMI, VGA and DVI-D ports together cements both fanless IPCs’ product positioning as the all-in-one, one-for-all solutions for almost all IoT, industrial automation and industry 4.0 deployment scenarios, particularly machine vision inspection, machine automation control and manufacturing execution system.

Also featured are 2.5″ HDD/SSD drive bays, mSATA socket, PCI/PCI-E expansion, mini-PCIe socket with SIM card reader, 9 to 30 Vdc input range, various mounting options and wide operating temperatures.

In conclusion, if you have expend a lot of resources on devices for your production line automatization (Regular pc’s, enclosures, etc. ) but nothing seems to work right in all environments, why don’t you think about investing on a long-term solution like industrial fanless PCs? Maybe you can start analyzing this first option from Lanner.