Background

Over the past few years, manufacturing sector has undergone a revolutionary change by implementing the concept of “connected and interconnected devices” to improve productivity and cost-effectiveness. With IIoT (Industrial Internet of Things) from conceptualization to now a reality, the manufacturing sector has witnessed an explosion of data generated on a daily basis. In fact, this unprecedented growth in data seems to have a continual increase due to AIoT (AI + IoT) technologies like Machine Learning, Machine-to-Machine network, high-performance automation and robotic equipment, which all generate mass volume of data.

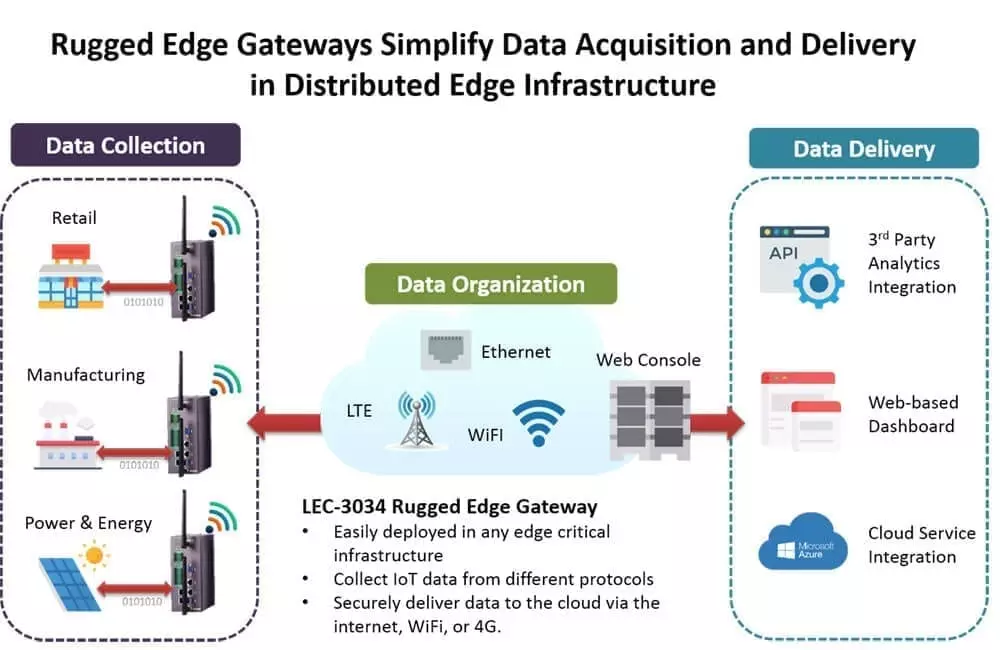

On the other hand, manufacturing sector has also adopted advanced facilities on factory floor such as access control, security control, video analytics, on-premise subsystems and PLCs (programmable logic controllers) with connection interfaces like BACnet, Modbus, Ethernet APIs, serial connectivity or analog/digital IOs. Such complexity has made gathering and collecting data an ever complicated work for data analytics in factory environment. Therefore, the manufacturing sector needs a simplified solution to data collection and communication to eliminate the complexity in data management.

Requirements

An US-based intelligent edge platform provider specialized in the operational intelligence for multi-sites, distributed facilities contacted Lanner to co-develop industrial gateways installed in factories by DIN-Rail mounting. Once the challenges have been identified, both parties have ensured that their joint solution, an embedded factory communication gateway, meet the following technological requirements:

- Wide operating temperature

Extreme ambient temperature may occur frequently in factory environments. Therefore, the joint solution must support wide operating temperature to have the necessary endurance in harsh environments.

- Multiple I/O Connectivity

To simplify data acquisition and collection for analytics, the joint solution will function as the industrial communication gateway on factory floors. Thus, the gateway shall be designed with multiple I/O connectivity to connect and communicate with other devices and equipment on the floor.

- Wireless Connectivity

Robust connectivity plays a critical role in the collection, organization and delivery of data -generated from devices on factory floors. The optimal hardware joint solution shall offer hard-wired Ethernet connectivity as well as a cellular backup in order to stay connected all the time so that rapid, real-time provisioning is enabled for newly deployed datacenters. No more on-site provisioning is necessary. In fact, the optimal joint-solution can function as the single source for all the data analytics at the edge.

- DIN Rail mounting form factor

DIN Rail mounting is by far the most space-efficient and practical way of on-site device installation in OT (operational technology) environment.

Solution

In this collaboration, Lanner introduced its LEC-3034, a rugged industrial edge gateway powered by onboard Intel® Atom E3825 processor (formerly BayTrail), 4G/LTE Mobile Connectivity (optional) and DDR3L SO-DIMM memory module supporting up to 8GB. The design of onboard Intel® Atom E3825 processor allows LEC-3034 to perform data analytic compute in wide operating temperature, from -40 °C to +70 °C. The DIN Rail mechanical design makes LEC-3034 a space-efficient and practical gateway on factory floor. As a rugged industrial gateway, LEC-3034 comes with multiple isolated COM ports (RS-232/422/485) and magnetic isolated LAN ports so that the connectivity I/O are protected from electrical or magnetic influences. LEC-3034 is built with a Mini-PCIe 3.0 socket that provides dual SIM card readers, so that 4G/LTE modules can be installed to enable wireless connectivity. With the features and functionality, LEC-3034 can be deployed as the single source gateway to simplify the data process for IIoT-ready factories.